Out in space, SPACE WALKER’s pressure vessels

will carry helium gas and nitrogen gas in rockets and satellites.

Here on earth, SPACE WALKER’s pressure vessels will be used in the future

for ultra-high pressure hydrogen storage and transportation,

playing an active role in tomorrow’s carbon-neutral and hydrogen society.

In order to realize this goal, our research and development team has been pursuing a pressure vessel that is not only sturdy enough for high gas storage efficiency and reliability, but is also ultra lightweight to reduce handling and material costs.

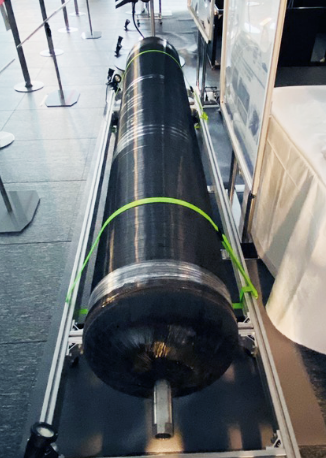

Our Type 4 pressure vessels have been developed with resin liners,

in contrast to typical Type 3 pressure vessels that employ metal liners

covered with carbon fiber.

By eliminating the use of metal, we have achieved significant weight

reduction and price reduction.

With a filament winding molding method,

we have succeeded in maximizing the strength of

our CFRP (carbon fiber reinforced plastic) material.

A minimal amount of filament winding is required to

achieve a maximum pressure resistance,

with significantly improved productivity.

Finally, as a leak prevention measure, a special finish is

applied at the joint area, eliminating the need for a separate

sealing member between the resin liner and the mouthpiece.

Research and development of an ultra lightweight composite vessel with a target weight reduction of 10% or more compared to linerless TYPE 4 pressure vessels.

We are researching and developing an ultra lightweight linerless composite vessel, TYPE 5, that is lighter than our TYPE 4 vessel which is made with a resin liner.

For use in transport equipment such as hydrogen trailers and cylinder bundles, composite container pressurizers for hydrogen stations, and fuel cell drones.

In our Proof Of Concept demonstration*, the pressure vessels achieved a design pressure of 105MPa, and a breaking pressure of 236.3MPa (safety factor 2.25 times).

※Currently preparing to obtain a Minister administrated special license and permit from the High Pressure Gas Safety Institute of Japan (KHK).

The resin liner is molded by rotational molding, and the mouthpiece is fused. Carbon fiber is wrapped around the liner using the filament winding method, and heated in a heating furnace to harden.

The tensile strength of carbon fiber is essential for burst pressure, which defines the main performance of a high pressure vessel, and is where the high specific strength of carbon fiber can be best utilized.

| Item | Detail |

|---|---|

| Filling Gas | Hydrogen |

| Design Pressure | 105MPa |

| Burst Pressure | 236.3MPa |

| Capacity | 30L/100L/300L |

| Hydrogen Permeability | 5cm3/L・H |